4 mins read

Published Nov 11, 2025

Mass Balance in Sustainable Supply Chains: Myths vs Reality

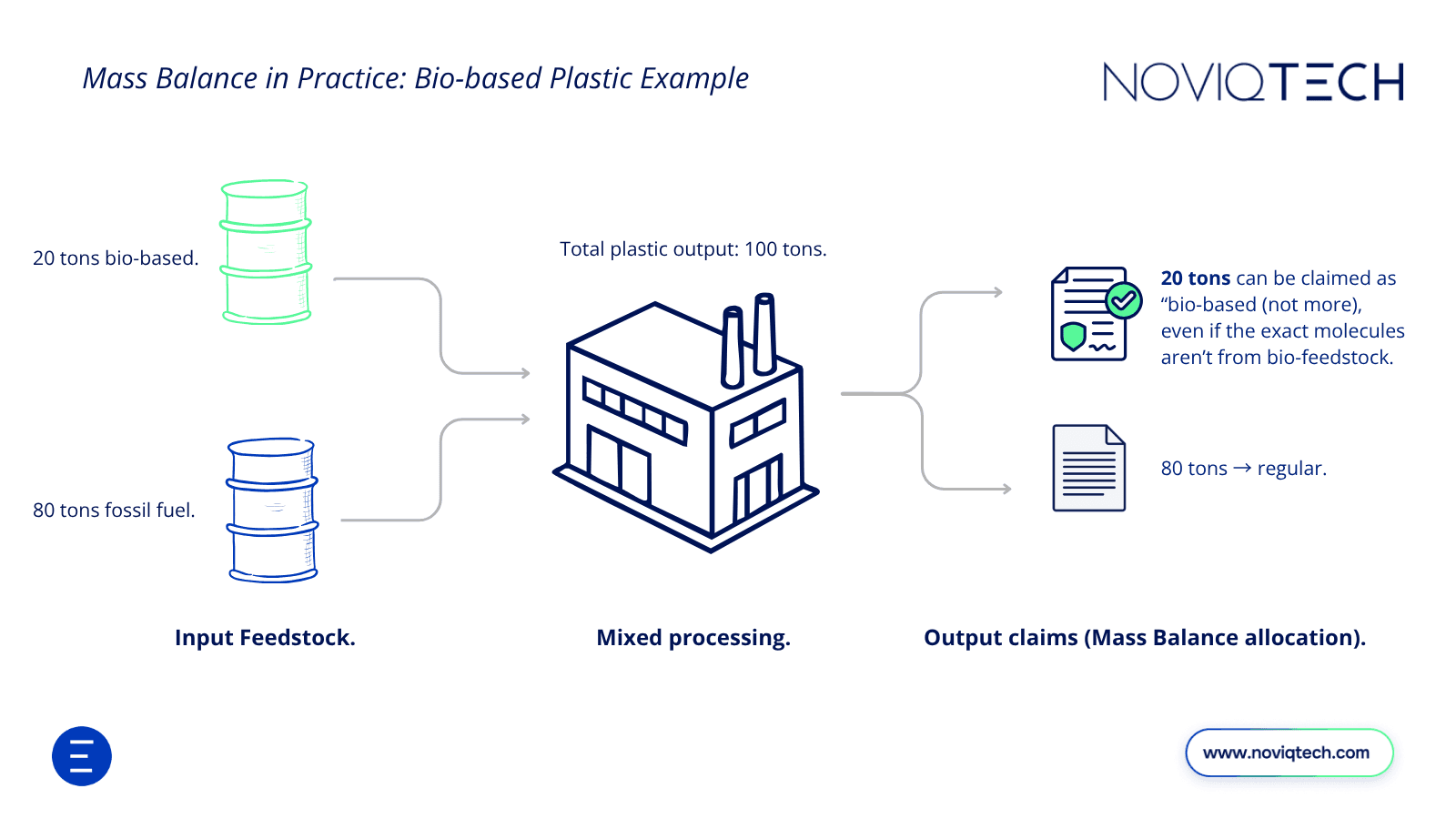

Mass balance is a traceability method that underpins many sustainable supply chains, yet it’s often misunderstood. While the term ‘mass balance’ has a wider application from a physics perspective in industrial applications, however, in sustainable supply chains where sustainable and non-sustainable inputs may be processed together, mass balance provides a methodology to attribute equivalent sustainability characteristics to the outputs through accurate bookkeeping and accounting systems.

In essence, it doesn’t require separating every unit of material while processing. Instead, you “balance” inputs and outputs through processing in your bookkeeping systems. In practice, this approach allows companies to mix sustainable and conventional feedstocks while 'attributing’ sustainability characteristics about a portion of their output.

Although mass balance is a widely used and accepted chain-of-custody model accepted by various sustainability frameworks and standards several myths persist around how it works and what it means for supply chain traceability.

Mass Balance: Common Myths vs. Reality

Let’s address some of the most common misconceptions about mass balance, and the reality behind each:

Myth #1: “Mass balance is just an accounting trick or greenwashing – the product isn’t truly sustainable if it’s mixed.”

Reality: Most products we use today are made through complex chemical processes that still rely heavily on fossil-based inputs, but this is gradually changing as bio-based, renewable, and recycled raw materials gain ground. To scale this transition, various industries are increasingly applying the mass balance chain of custody model that enables certified sustainable inputs to be integrated into existing infrastructure and proportionally attributed to outputs. By ensuring that certified outputs never exceed certified inputs, mass balance provides a credible, verifiable way for companies to grow the share of sustainable materials, make trustworthy claims on finished products, and accelerate the shift towards a more circular, lower-carbon economy.

Myth #2: “You can’t trace or verify anything with mass balance since everything gets mixed together.”

Reality: It’s true that physical tracing down to the molecule is impossible when a variety of materials are mixed together for processing. However, mass balancing requires robust administrative traceability of the inputs and outputs through a process or a facility, whereby ensuring that the ‘sustainable’ attribute is only assigned to the portion of outputs equivalent to sustainable inputs. Facilities using mass balancing are required to maintain extensive records of their production process in a mass balance ledger that is subject to independent audit. Various certification schemes (ISCC, RSB) and regulations (EU RED III) require detailed mass balance as a chain-of-custody control to prevent any double counting or label misuse. Noviqtech’s sustainability platform Carbon Central further enhances traceability: each unit of tracked materials are logged with unique IDs and timestamps, using blockchain-based tokens to create an immutable record of every batch’s data, providing full traceability and transparency for mass balance transactions.

Myth #3: “Mass balance lets companies cheat by allocating all the ‘good stuff’ to certain products on paper.”

Reality: One of the core requirements of mass balancing is that a facility cannot allocate more sustainable content to the output than they received as input. In addition, different types of attribution rules also apply regarding accounting for processing losses, consideration sustainability attribution to material vs energy outputs, etc. to ensure accurate accounting of the processes. At a high level, mass balance enables a ‘systems perspective’ of looking at materials and fuels processing, thereby enabling the transition to a more sustainable and circular economy by allowing the increase in share of sustainable materials and fuels within the current infrastructure and systems.

Figure 1: The Mass Balance Chain of Custody Model - Bio-based plastic example.

Making Mass Balance Work: Tools and Best Practices

Implementing mass balance successfully requires a combination of internal process tracking, digital tools and technology, and certifications for sustainability frameworks:

Follow Established Standards: Third-party certification under recognised sustainability frameworks (such as ISCC, RSB, or other RED-compliant schemes) is essential to ensure credibility and trust in the mass balance system. These certifications verify that the certified feedstocks meet defined sustainability criteria and that companies adhere to the chain of custody rules. Certification provides external validation that the share of sustainable inputs attributed to products is accurate, helping businesses make credible claims in line with international standards and giving customers confidence in the integrity of the process.

Tip: If you want to learn more about these certifications and how they differ, check out our article that breaks down ISCC, RSPO, RSB and others in detail.

Use Digital Tools for Data Traceability: Digital platforms are essential for accurate, scalable mass balance implementation across sites, production processes and organisations. NoviqTech’s Carbon Central replaces manual bookkeeping and spreadsheets by automatically capturing inputs and outputs from various sources of data on site. Every unit of output is issued a tamper-proof digital certificate on the Hedera blockchain, ensuring traceability and auditability. With built-in calculators and reporting tools, the platform delivers accurate Proof of Sustainability (PoS) documents and audit-ready mass balance reports, reducing errors and providing high traceability.

Internal process tracking: Successful mass balance implementation starts within the company’s own operations. This requires clear procedures to monitor material flows, ensure accurate allocation of sustainable and non-sustainable inputs, and prevent double counting. Internal controls must be robust, with traceability systems that link procurement, production, and sales data for audit purposes. Regular staff training and clear governance structures are also critical to maintain accuracy and consistency across departments and sites.

Conclusion

Mass balance is a proven, internationally recognised method that enables companies to credibly increase the share of sustainable inputs within existing supply chains.

By ensuring certified outputs never exceed certified inputs, it provides a transparent, auditable basis for sustainability claims that withstand scrutiny from regulators, auditors, and customers.

Beyond compliance, mass balance supports incremental substitution of fossil-based materials with certified sustainable alternatives, offering both environmental impact and market advantage.

In short, it transforms sustainability from a broad ambition into a verifiable, data-driven process that can be applied today to build trust and accelerate progress toward circular, low-carbon value chains.

If you’re exploring how to implement the mass balance model across your operations, our team can help you structure the process and ensure full traceability. Contact us here.