4 mins read

Published Oct 9, 2024

Closing the Loop on Glycol: NoviqTech’s Visit to Global Resource Recovery (NT)

Since the announcement of a partnership with Global Resource Recovery (NT) (GRR), NoviqTech had the opportunity to visit GRR’s facility based in Darwin, Australia to learn more about their innovative glycol recycling process and to better understand how this process will be fully integrated with the Carbon Central platform.

A Warm Welcome and Introduction to the Facility

Located in Darwin, NT, Australia, Global Resource Recovery (GRR) operates one of the most advanced and state-of-the-art chemical recycling and reclamation facilities in the region. Upon our arrival, we were welcomed by GRR’s team, who offered us a tour of their plant, equipped with cutting-edge technologies and sustainable practices. The site visit began with a site induction and briefing on the importance of glycol recycling, explaining how spent glycol from industrial applications (like as dehydrating agent in the LNG industry) can be reprocessed rather than discarded.

Picture of Dipam Gandhi and Freddy El Turk at GRR Darwin Facility

Our primary objective was to understand the nuances of the glycol recycling process, learn about the environmental benefits, and evaluate how we can contribute through tokenised solutions to create Guarantee of Origin (GO) certificates and track carbon emissions savings of recycled glycol.

Understanding the Recycling Process: From Waste to Resource

The GRR facility uses a multi-stage process to recover glycol with high efficiency and purity. The process involves:

1. Collection and Storage: Spent glycol is collected, filtered and stored in purpose-built storage tanks, making it ready for the next step in the process. A sample from the material received is lab tested at site to examine the proportion of contaminants to be removed from the material.

2. Evaporation: At this stage, excess water is removed from the material. The water removed is collected and processed through an on-site Wastewater Treatment (WWT) facility such that the treated water can be safely taken away through waste management arrangements.

3. Distillation: At this stage, the highly concentrated glycol solution is distilled, separating pure glycol from chemical residues and salts, which are further processed and treated for disposal.

4. Quality Testing: Rigorous quality checks ensure the recycled glycol meets industry standards and customer requirements, making it suitable for a variety of applications.

We also witnessed first-hand how GRR centrally controls and manages their entire operations on site through various systems, tracking each phase with precision and dedication to environmental stewardship. This aligns perfectly with our data-driven approach at NoviqTech to promote resource-efficiency and circular economy.

The Environmental Impact: Circular Economy in Action

Recycling glycol is not just about reclaiming a chemical; it’s about reducing environmental harm and promoting circular economy. Disposing of used glycol is challenging due to its toxic properties, and improper disposal can lead to soil and water pollution. GRR’s approach not only prevents these adverse effects but also contributes to reducing the demand for virgin resources, conserving energy, and cutting greenhouse gas emissions to a great extent.

At NoviqTech, we are passionate about supporting circular supply chains, and GRR’s plant demonstrated how effective recycling can close the loop in industrial waste management. This experience also validated the potential for our blockchain-based digital twin solution within Carbon Central, which could trace each unit of recycled glycol and verify its origins, ensuring authenticity and transparency.

Exploring Collaboration: Digital Twins and Tokenisation

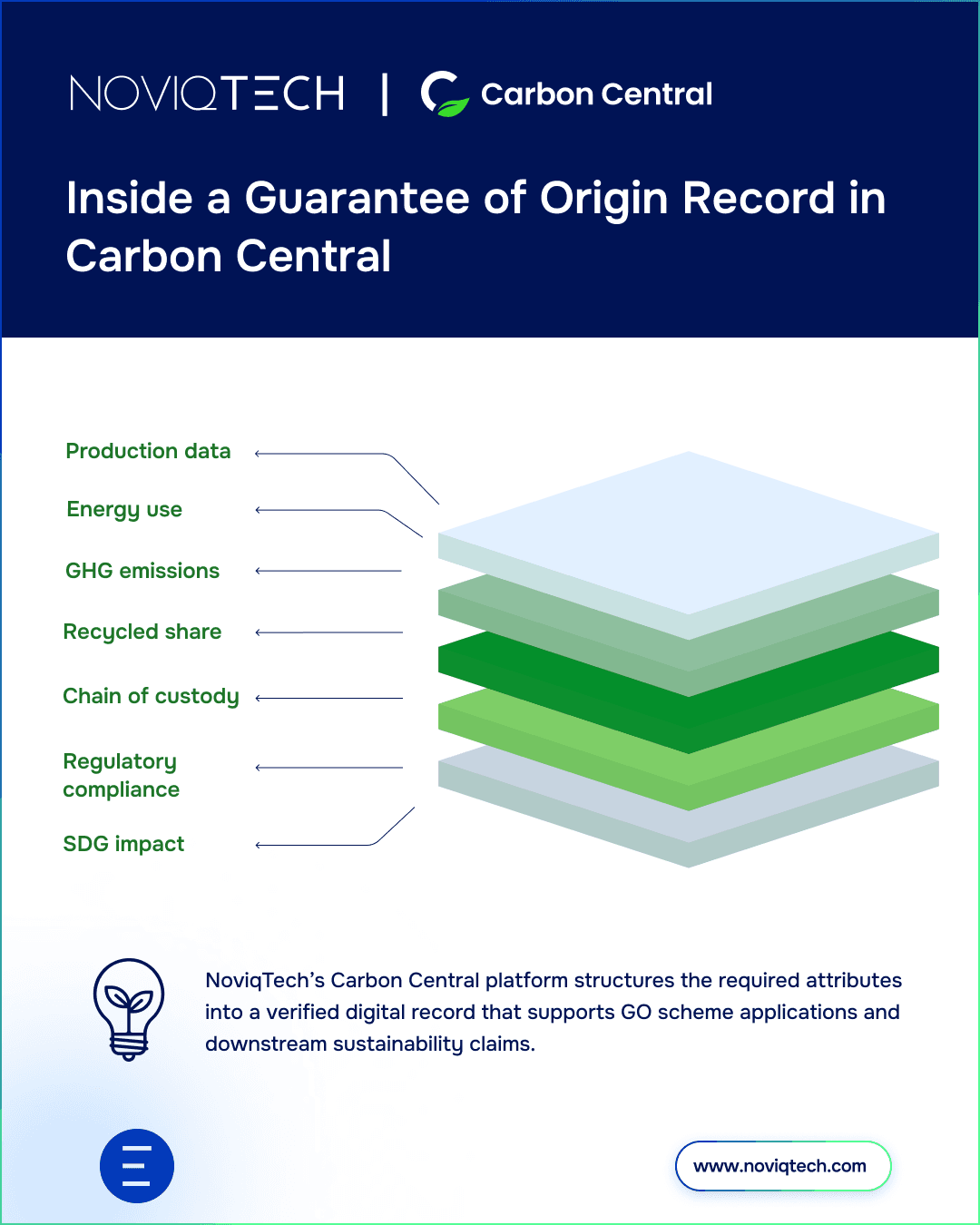

Our visit was at GRR was an exciting learning experience about how an industry-leading process can benefit a whole industry in many ways. As NoviqTech develops a digital twin for Guarantee of Origin tracking for GRR, we see significant synergy in integrating our systems with GRR’s operational data. Through blockchain-based tokenisation, each unit of recycled glycol will carry a unique digital footprint, from its point of origin to its re-entry into the market, tracking material and emissions.

Our discussions with GRR’s team included our technology could enhance transparency, verify sustainable practices, and promote circular economy, incentivising industries to choose recycled glycol over virgin alternatives.

Figure 1: Inside a Guarantee of Origin Record in Carbon Central

What Lies Ahead

As we finalise our digital twin for GRR, we are excited to see the value and benefits that our Guarantee of Origin solution brings to GRR and the industries they support. Our partnership with GRR is an amazing example of how NoviqTech supports sustainable supply chains and promotes circular economy through our solutions.